EPA Method 9216

The United States Environmental Protection Agency (USEPA) initiated a project with various stakeholders for a condensible particulate matter (CPM) test method study to improve USEPA Reference Method 202 (RM 202) for CPM. The project is an outgrowth of the “Proposed Rule to Implement the Fine Particle National Ambient Air Quality Standards,” proposed on November 1, 2005 (70FR65984). USEPA’s project is a comprehensive test program consisting of three distinct phases as follows: Phase I—Side-by-side bench testing of RM 202 and the improved CPM method, Phase II—fieldtesting the improved method, and Phase III—emission factor development.

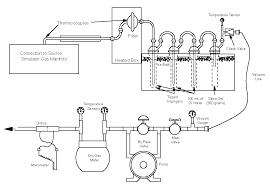

The Alliance of Automotive Manufacturers (Alliance), a stakeholder for this study, is providing this report to contribute to Phase II—comparing RM 202 to the improved method through field testing. The stationary source chosen for this application is a wet machining operation associated with an oil mist collector control device that serves an automotive machining process for transmission components. The source’s flue gas temperature was less than or equal to 85 o F. The Alliance retained Bureau Veritas North America, Inc. (Bureau Veritas) to conduct Phase II field testing for the Particulate Matter RM 202 study. The study consisted of simultaneous testing of condensible particulates with RM 202 and the improved method defined in Phase I.

On March 29th and 30th, 2007, side-by-side simultaneous stack testing studies comparing RM 202 to the improved method were conducted. In this application, the data revealed the improved method does not indicate a significant statistical difference from the traditional RM 202 based on precision and accuracy and, therefore, is an acceptable methodology for the determination of CPM. The improved method data also indicated that sample train temperatures equal to or less then the flue gas temperature (i.e., 85 o F for this application) reduced the organic fraction of the condensed phase by approximately 50%. The remaining organic fraction was located on the primary filter. By comparison, in the traditional RM 202, approximately100% of the organic fraction is found when extracted from the wet impingers.

There are no products listed under this category.